Source: China Machine Vision Network

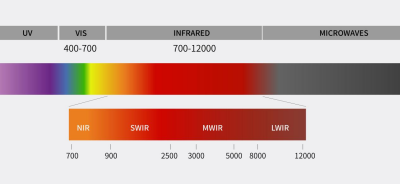

Short-wave infrared imaging technology (SWIR) comes from spectroscopy and infrared radiation physics, and it is an advanced imaging technology based on the wavelength range of infrared radiation. Its wavelength coverage range is usually 900~1700nm (see Figure 1). This spectral region mainly records the frequency doubling and harmonic vibration information of organic compounds or hydrogen-containing groups (such as C-H, O-H, N-H, etc.) in macromolecular groups, for example

Infrared radiation in this band has a very special ability, which can penetrate most materials, such as smog, smoke, plastic and glass, and can work in low lighting conditions, which makes it perform well in complex environments.

Fig. 1 Schematic diagram of short wave infrared (SWIR) hyperspectral band.

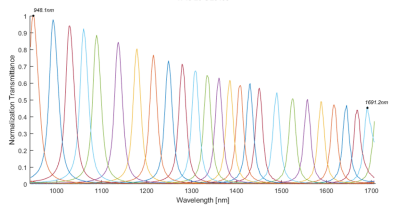

Based on the Fabry-Perot interference principle, the short-wave infrared hyperspectral imaging technology (SWIR-HSI) with nanometer sea spectrum puts a tunable filter in front of the image sensor. By filtering the light in different bands of SWIR (the filter curve is shown in Figure 2), the complete image of each spectral band can be quickly collected to generate three-dimensional spectral cube data.

The cube data contains spectral information related to substance composition and image information related to object shape, which can efficiently, accurately and anti-jamming locate the positions of different substances in the image, and analyze the composition and content of different substances. The successful research and development of SWIR band hyperspectral camera can broaden the application of hyperspectral camera in the fields of image and substance detection, such as agriculture, food, papermaking, wood, cosmetics industry and biomedical imaging.

Fig. 2 Schematic diagram of short-wave infrared hyperspectral data curve

Application direction

(1) machine vision AI

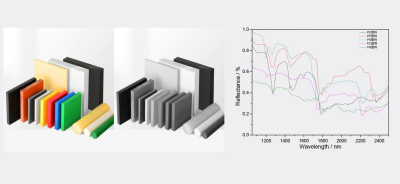

The development of hyperspectral machine vision plays an important role in the control of robots. SWIR hyperspectral camera can detect product defects and specific material characteristics that are invisible to the naked eye, and can help robots collect information of material components in different environments (see Figure 3), which opens up a wide application space for machine vision solutions and enables terminals to better understand the world.

Fig. 3 Spectral curves of different plastic materials.

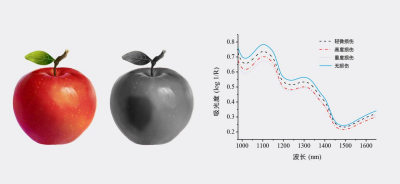

2) Quality inspection of fruits and vegetables

In the imaging of SWIR hyperspectral camera, the moisture content in fruits can be clearly detected, and local defects can be detected. As shown in fig. 4, using 1450nm imaging to detect, the damaged parts of the apple are darker in color, while the normal parts are lighter in color.

Fig. 4 Spectral curve of fruit damage area detection

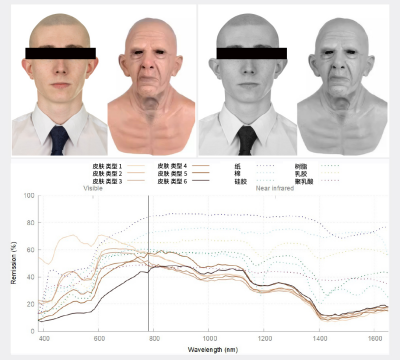

(3) Biometrics

SWIR hyperspectral camera can be used to identify people's camouflage, such as makeup, wigs and glasses. SWIR hyperspectral imaging uses the characteristics of 900~1700nm infrared spectrum to detect the reflection and radiation characteristics of objects, which can penetrate camouflage materials and obtain the real information of objects.

Fig. 5 Spectral curves of human skin and artificial materials.

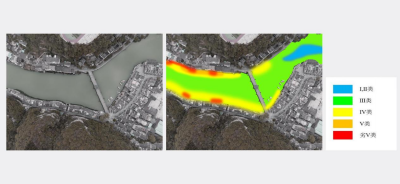

(4) Environmental monitoring

SWIR hyperspectral camera has the ability to take pictures through rain, fog, smoke and other shelters. As shown in fig. 6, the RGB image of a common camera cannot detect the clear and visible image on the left; However, the SWIR hyperspectral camera can penetrate the atmospheric shelter to determine the real situation behind it.

Fig. 6 Aerial hyperspectral regional map of river water quality.

SWIR hyperspectral camera is widely used in many fields, but it is still accompanied by some application limitations, such as high cost, camera size, power consumption, data processing, and material characteristics. These limitations have prompted the field of science and technology to explore and innovate constantly to overcome these challenges and provide a wider, more flexible and more practical SWIR hyperspectral camera solution to meet the needs of different application fields.

Realize mass production

Recently, Haiping Nano announced a major technological breakthrough, and realized the mass production of short-wave infrared hyperspectral cameras based on MEMS technology for the first time in the industry.

SWIR hyperspectral camera based on the hyperspectral MEMS-FPI sensor chip is a new generation of hyperspectral camera, which is made by bonding the MEMS hyperspectral sensor chip with the image sensor by using the related technology of MEMS semiconductor manufacturing process. Compared with the traditional technology, the volume of the module is reduced by 10,000 times, and the power consumption is only milliwatts, which has obvious advantages in cost control and identification accuracy.

With profound technical accumulation, Haiping Nano has made continuous innovations and breakthroughs in the hyperspectral MEMS imaging sensor with light weight, high cost performance, low power consumption and mass production, and will vigorously expand its application in many industries.

Mr. Huang Jinbiao, founder and CEO of Haipu Nano, said: "This product is a new milestone for Haipu Nano. We believe that only MEMS hyperspectral imaging technology can better meet the needs of downstream visual AI for material composition exploration. In the future, Haipu Nano will continue to work with partners in the upstream and downstream of the industrial chain to build a hyperspectral ecological chain and apply MEMS hyperspectral imaging technology to related industries. "