Online Printing Quality Detection System

Product features:

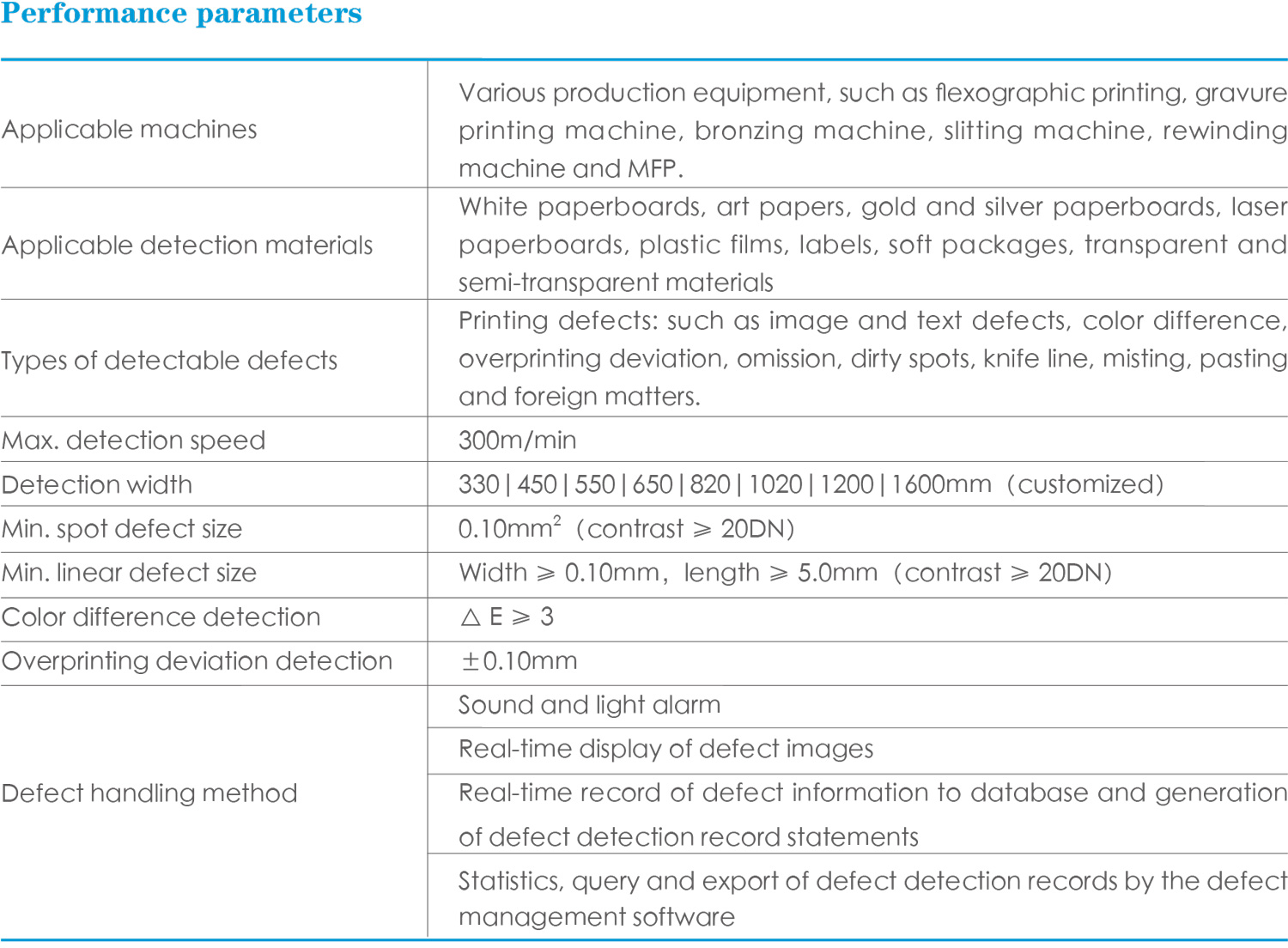

◆ Real-time detection of continuous defects of image and text detects, color difference, overprinting deviation and omission, as well as real-time sound and light alarm to remind timely manual adjustment so as to reduce the reject rate and production costs;

◆ Max. detection speed 300m/min, and real-time monitoring of production state;

◆ Rapid modeling to improve production efficiency;

◆ Display and record the defect information in real time for subsequent screening and removal of defective products;

◆ The defect detection records are stored in the database and can be browsed and queried in the defect management system. Data statistics can be performed on defect information, and defect detection statistical statements can be exported to provide data support for quality management.

Product advantages:

◆ It is intelligently linked with MES system, records the outputs in real time and saves the detection results to cloud to master the production progress at any time and any place;

◆ The brand new imaging solution can identify all defects, track the defects in a more convenient way and automatically capture all continuous defects;

◆ 2 min intelligent modeling realizes the automatic product extraction, automatic positioning, automatic text extraction and automatic two-dimensional code extraction;

◆ 0.10mm ink drawing inspection and text detection algorithm;

◆ More user-friendly operation modes: defect view at multiple magnification, visual modeling and flat interactive interface.

Video introduction:

Flexo Web Inspection System

Rotary Book Press Monitoring System